Uranium & Plutonium Combustion Testing

Comparison of a Semi-Analytical and A CFD Model of Uranium Combustion to Experimental Data

ABSTRACT

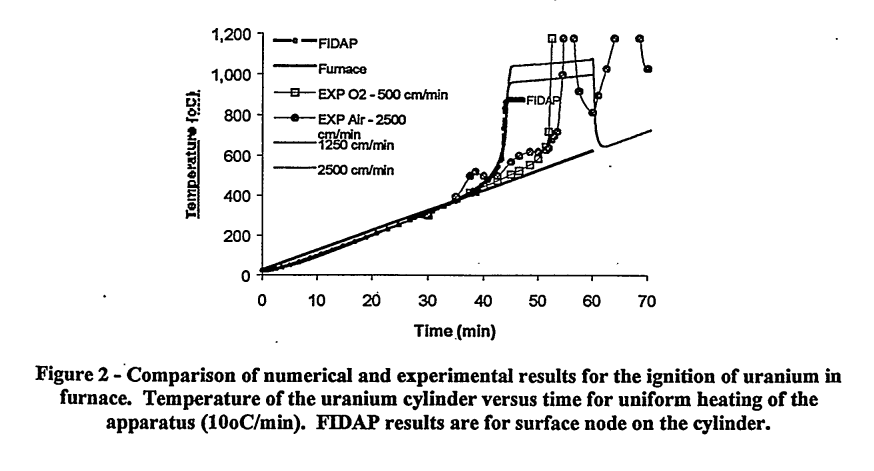

Two numerical models were developed and compared for the analysis of uranium combustion and ignition in a furnace. Both a semi-analytical solution and a computational fluid dynamics (CFD) numerical solution were obtained. Prediction of uranium oxidation rates is important for fuel storage applications, fuel processing, and the development of spent fuel metal waste forms. The semi-analytical model was based on heat transfer correlations, a semi-analytical model of flow over a flat surface, and simple radiative heat transfer from the material surface. The CFD model numerically determined the flowfield over the object of interest calculated the heat and mass transfer to the material of interest and calculated the radiative heat exchange of the material with the furnace. The semi-analytical model is much less detailed than the CFD model, but yields reasonable results and assists in understanding the physical process. Short computation times allowed the analyst to study numerous scenarios. The CFD model had significantly longer run times, was found to have some physical limitations that were not easily modified, but was better able to yield details of the heat and mass transfer and flow field once code limitations were overcome.

Want to know more? This is an abstract of a paper published in 1998 at the 6th International Conference on Nuclear Engineering, ICONE-6, May 10-14.